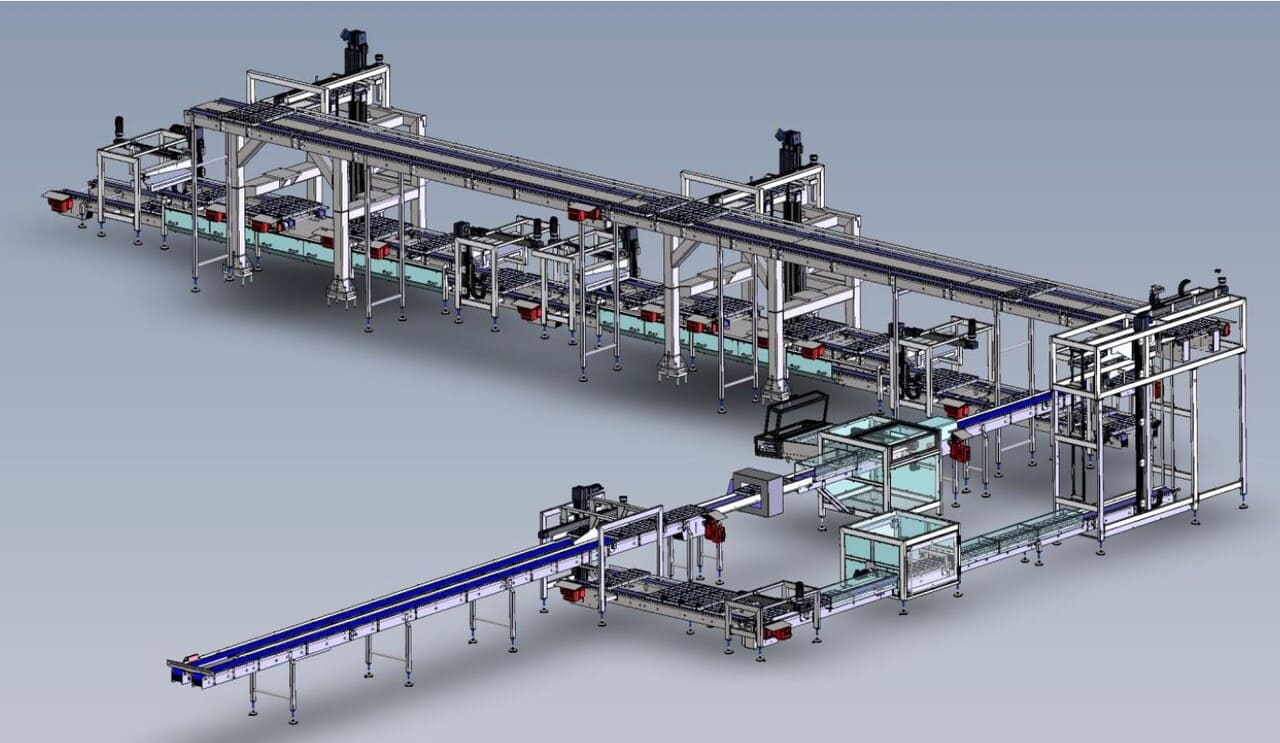

Countermoulds lines

Specialised solutions for transferring chocolate to wrapping machines, directly from the moulder outlet, ideal for hollow products and various types of pralines.

Technical features:

AISI 304 structures.

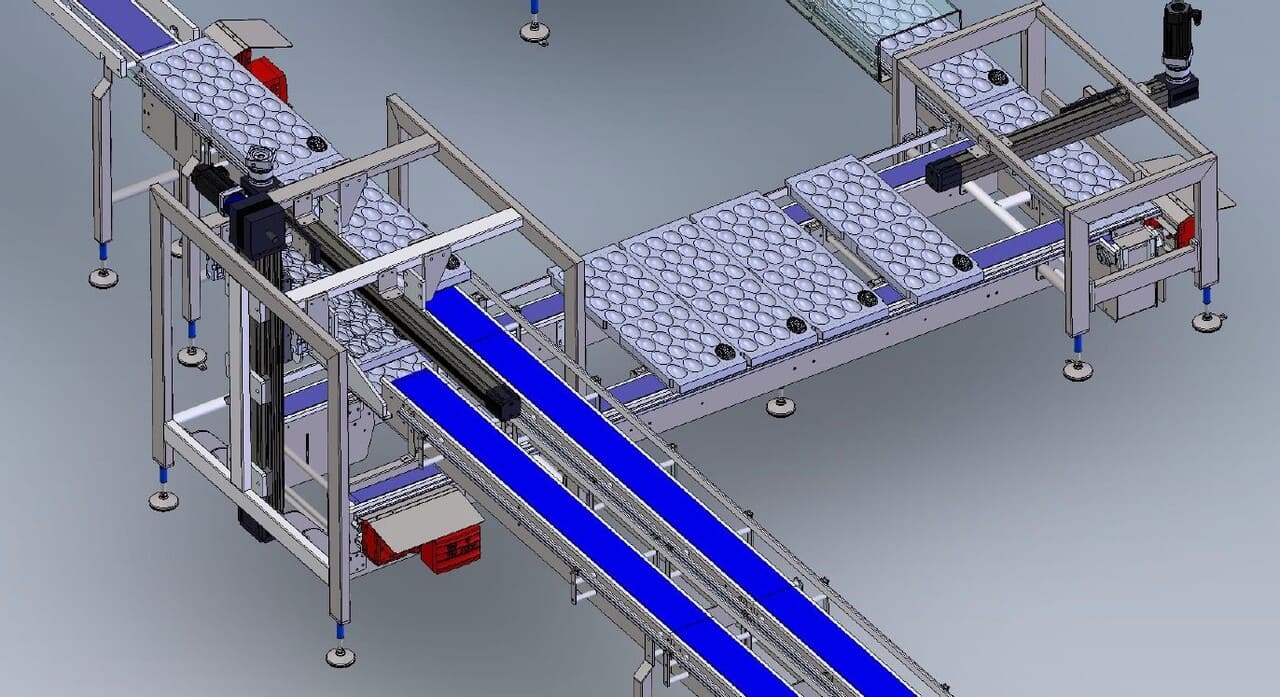

Double track systems with table top or modular.

Nylon chains with high abrasion resistance.

Versions available for chocolate lines or tray lines for bakery products.

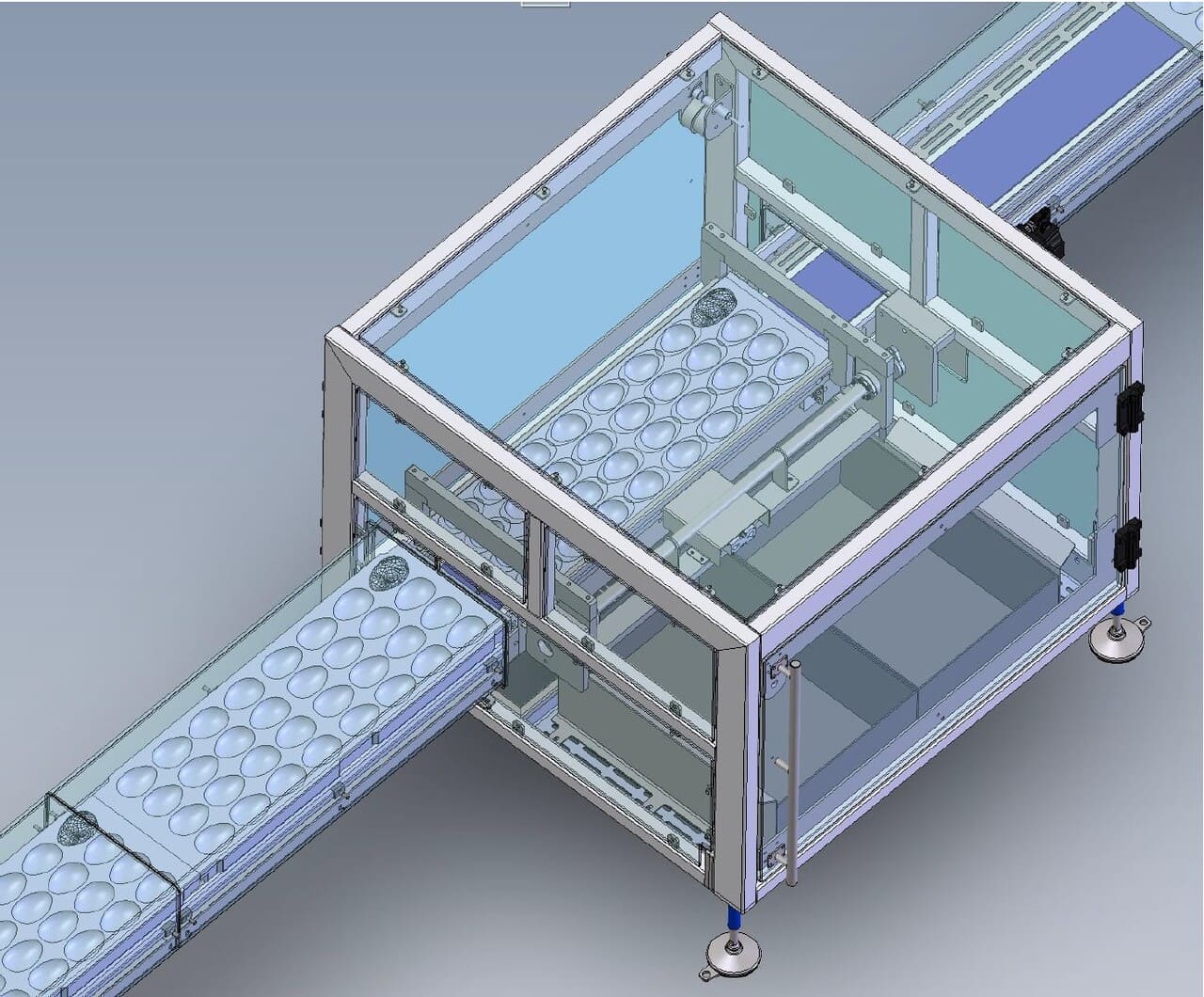

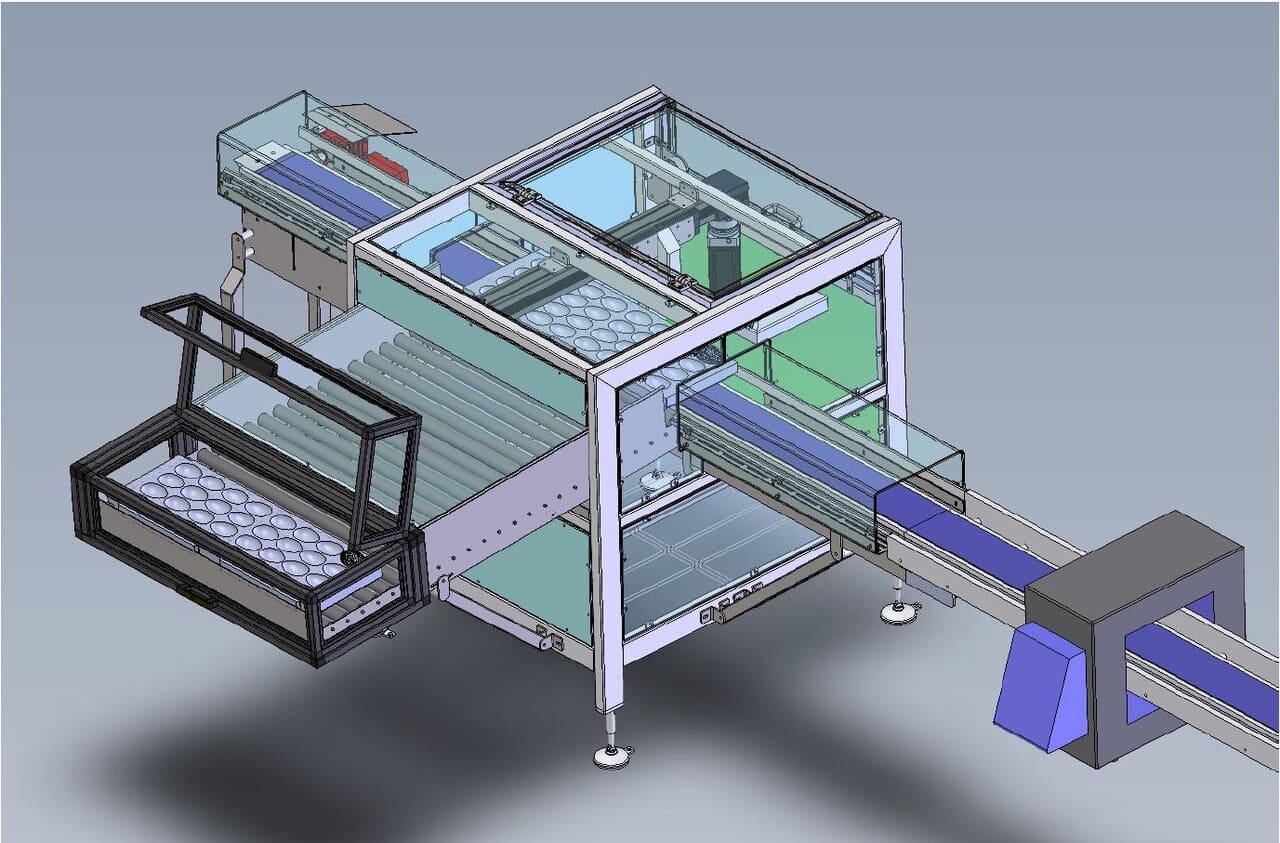

In the wrapped chocolate market, packaging lines are divided into three main parts: the moulding line, the wrapping line and the boxing and palletising line. After the moulding process, the products are transferred onto plates called 'countermoulds' which feed the wrapping machine. Once emptied, these plates are returned to the beginning of the line to be reused.

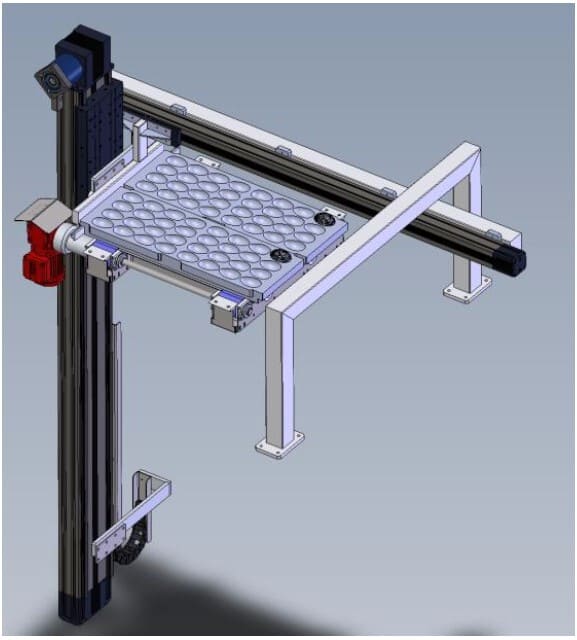

Essential equipment for these operations includes:

- Single and double lane conveyors

- Ejection systems after metal detector

- Elevators

- Pater Noster

- Plate tipping devices

These systems ensure a continuous and efficient flow of plates along the packaging line.

A very similar type of line, both in terms of conveyor construction and accessories, are the tray lines found in the bakery sector. In this case, the trays are transported directly, in the processing part before the oven and in the cooling part, up to the rack, after the oven.

In these lines, however, there is no 'counter-moulding' part, and after slitting we pass onto conveyor belts that feed the packaging machines by means of chicane systems or row extraction lines.