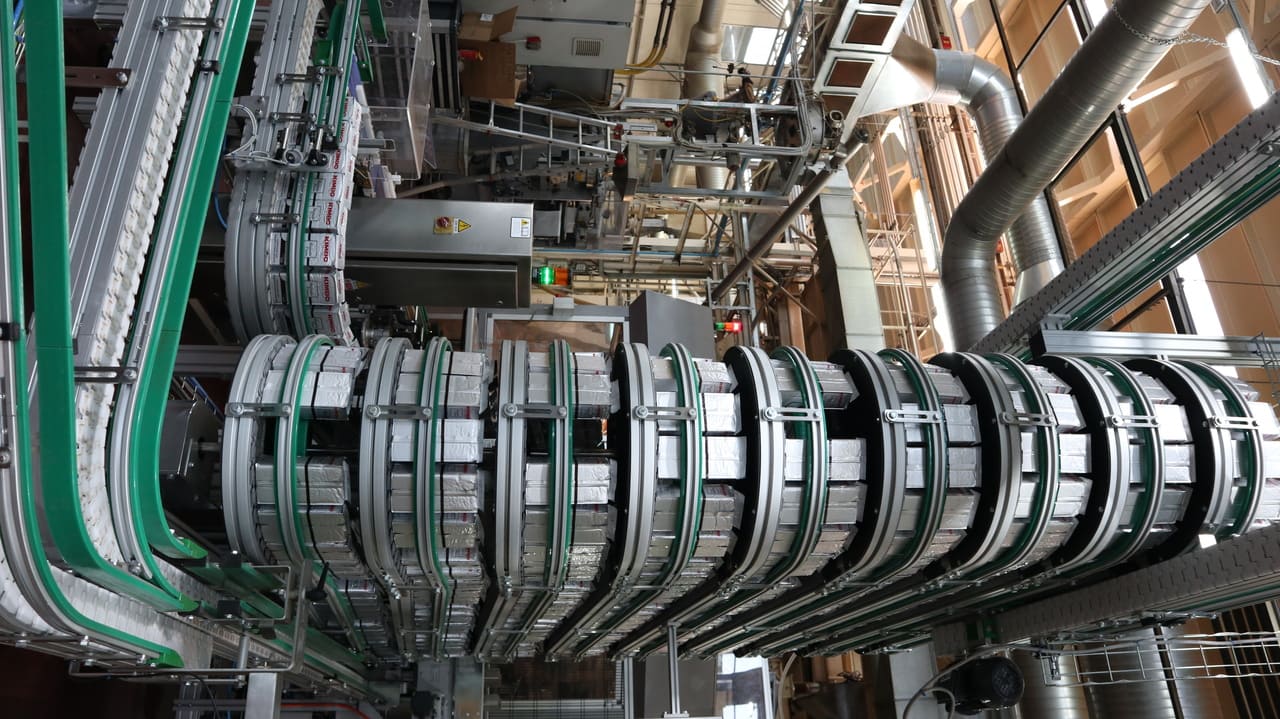

Bat Buffer

The BAT-Buffer is a flexible, reliable, zero pressure, LIFO storage system with a small footprint.

Technical features:

- Floor space: approx. 2 metres wide, 4-6 metres long

- Height: up to 5-6 metres

- Frame material: anodised aluminium or AISI 304

- Strip width: 83 or 114 mm

- Accumulation: 50 to 150 m

- Productivity: 120 - 250 ppm

The BAT-Buffer is the most flexible accumulation system in our solution portfolio, configurable to fit many different products. The standard machine has an anodised aluminium structure and consists of a spiral with sharp bends and straight sections, made with table top chains that allow tangential pulling. The spacing between the curves of the spiral can vary from 3 to 6 m, offering up to 150 metres of storage space with a single motor in a relatively small footprint.

The system operates with LIFO logic and, if the downstream machines have 10-20% extra capacity, allows for the elimination of end-of-shift losses.

The products are fed through a diverting system on the main line which, when the downstream machine stops, moves the incoming products onto a buffer conveyor. From this conveyor, the products are guided into the buffer system.

Thanks to the action of the inverter, it is possible to place the products on the buffer while maintaining a certain pitch so that they do not come into contact with each other and do not crush, preventing possible damage.

When the downstream machine becomes available again, the BAT-Buffer reverses its direction of travel and enters the unloading phase. The products are fed back into the line by means of a unification device so that the buffer can be emptied at the same time as normal line operation. The make-up unit has two possible modes of operation:

- In the case where the products must necessarily maintain the direction of travel in which they entered the buffer, there is a system for returning the products via orthogonal transfer, possibly stopping upstream production for a few seconds, provided that the products allow a minimum of mutual accumulation.

- If the direction of travel of the products is indifferent for production purposes, restitution is by means of a dynamic unifier with timing belts, ideal for fast lines. This configuration also allows the buffer to be emptied at full line speed in the event that upstream machines are momentarily stopped.

TYPICAL PRODUCTS

The BAT-Buffer is ideally suited for bakery, confectionery, coffee and other vacuum-packed products or in general for all those products that have a rather long shelf life. The system is also available with AISI 304 construction in case it has to be placed in a white area and has to undergo occasional washing.