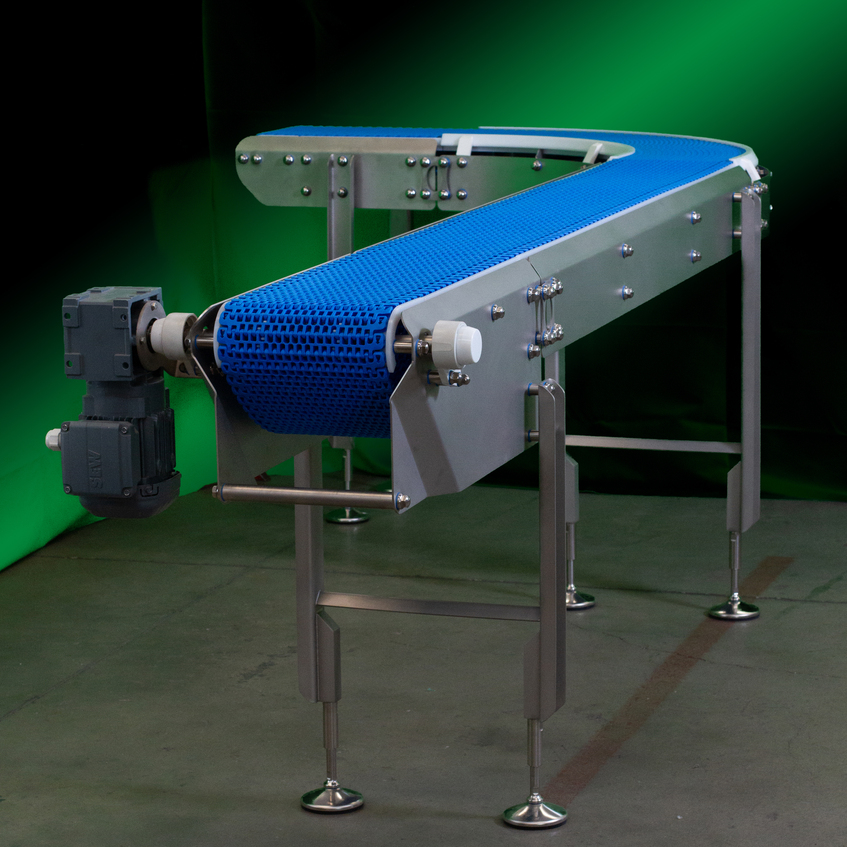

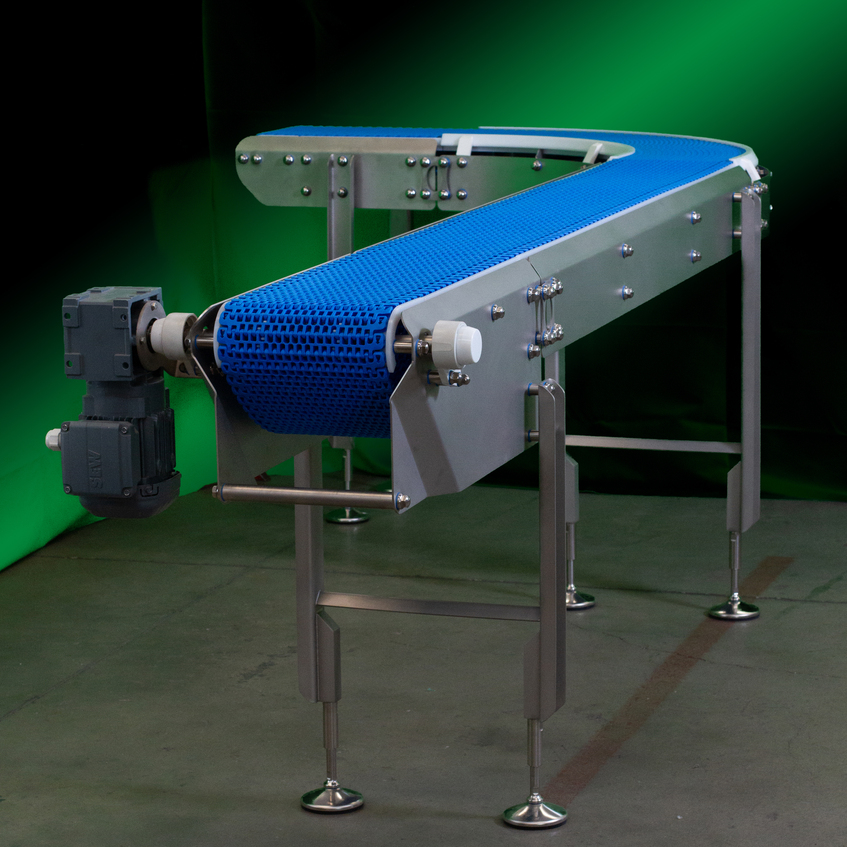

SaniFlex

A new modular conveyor system that meets the highest standards of hygienic design.

Technical features:

- Structure in AISI 304

- No horizontal surfaces

- No coupling between flat surfaces

- Open frame easily washable

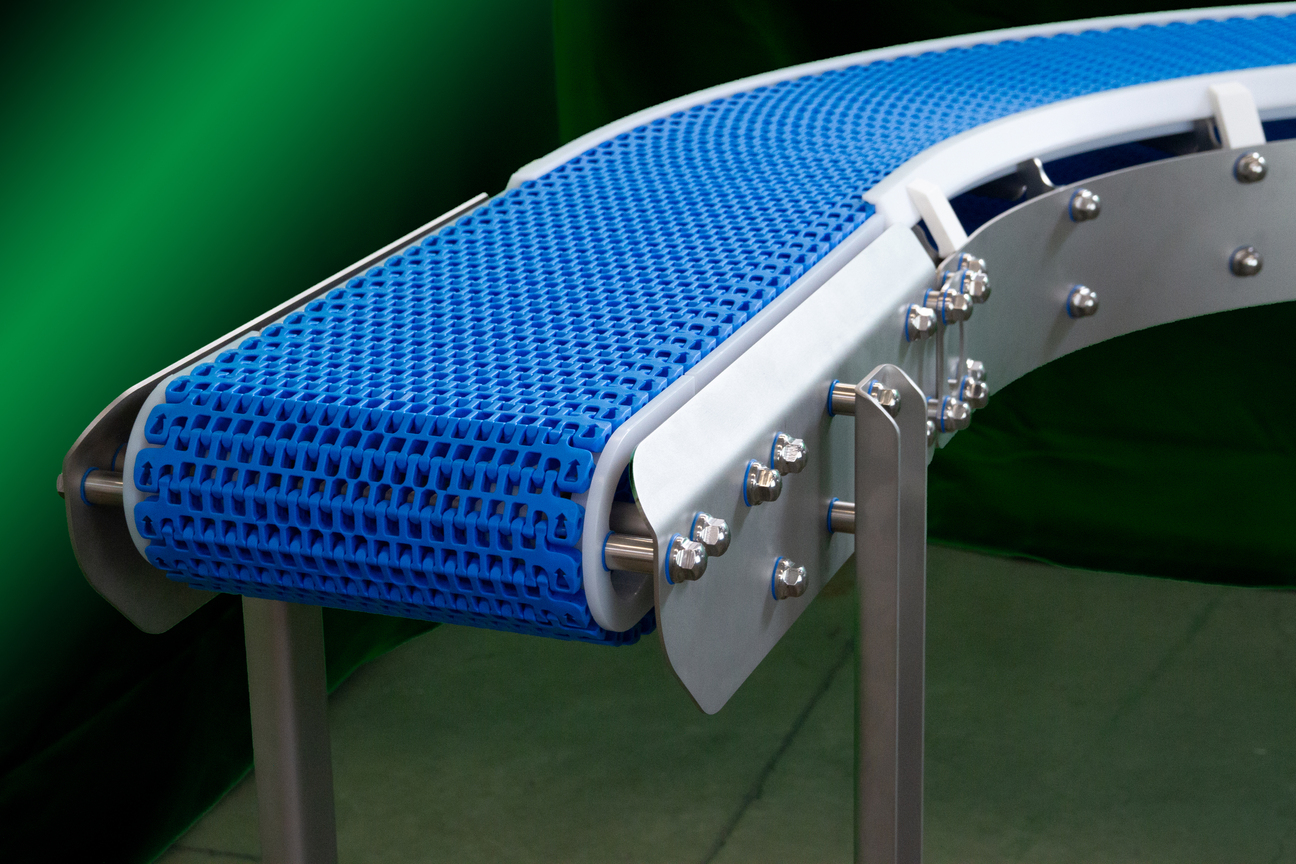

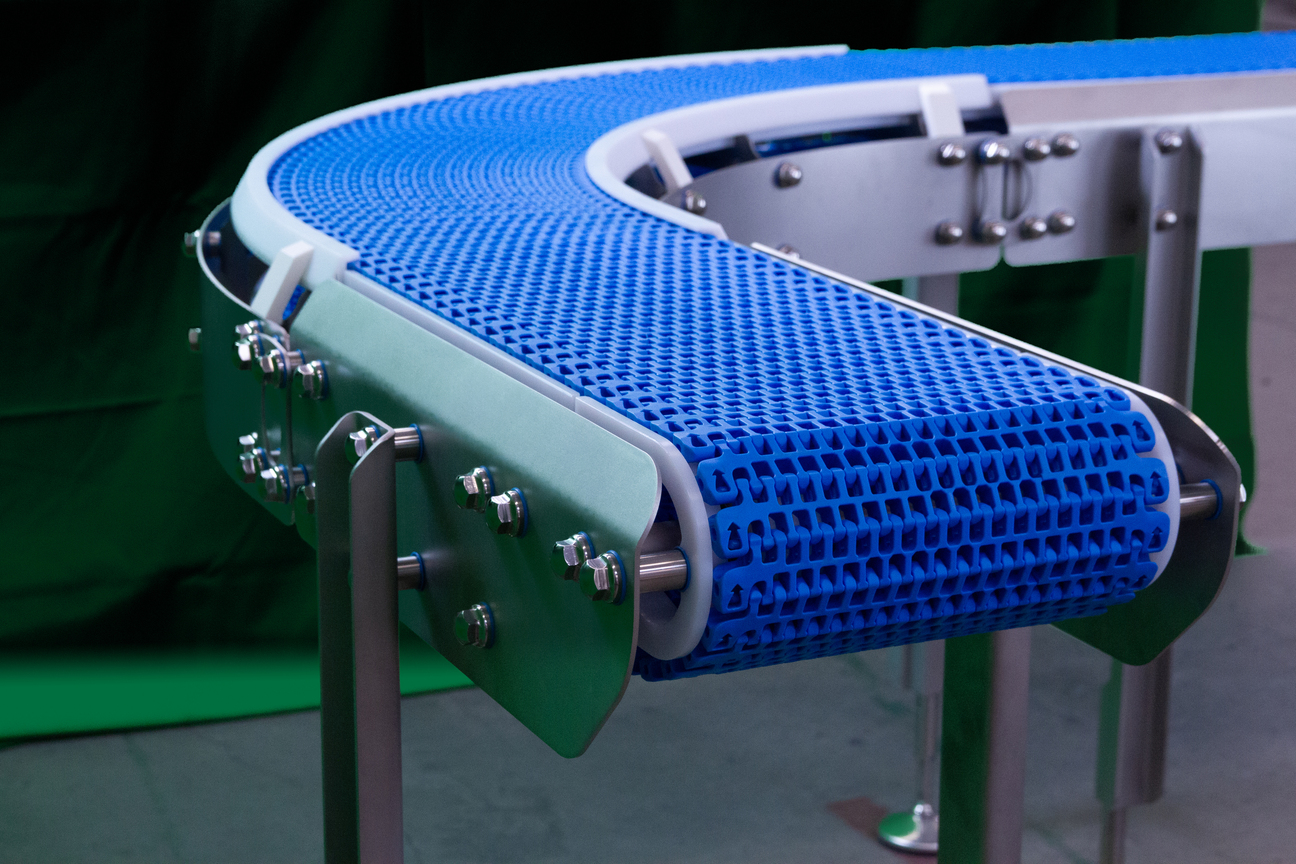

- Chain free and liftable by hand during cleaning cycles

- Sliding profiles interlocking

- No visible threads

- Continuous welds

- No hollow tubes

- Bolts and nuts with detectable blue seals

- Food-grade certified components

- Available widths 152, 254, and 506 mm

- Speeds up to 60 m/min

The Sani-Flex system is designed to ensure the highest levels of accessibility and ease of cleaning. It is inspired by USDA guidelines for dairy machines, making these conveyors capable of handling any unpackaged food.

The entire structure is open and accessible and the tracks can be removed without the use of any

tools. A simple flathead screwdriver allows the modular chain to be unbolted. The frame has no flat or concave surfaces, thus eliminating any stagnation points. All components are certified for food use and there are no flat surfaces in contact with each other; all fasteners are fitted with gaskets to prevent areas where bacteria can form.

The chain chosen is the latest iteration of Intralox's famous 2400 Series. On the Sani-Flex, we chose the HeavyDuty version, in blue polypropylene with polyketone pins, the best compromise between mechanical performance and resistance to chemicals. Specially designed to allow operators to work directly

on the conveyor, it guarantees greater safety and smooth, silent operation.

The sum of all these features provides the end user with a conveyor system that is easy to use, maintain and clean, with less consumption of water, detergents and power. A sustainable solution for the current and future needs of the food industry.