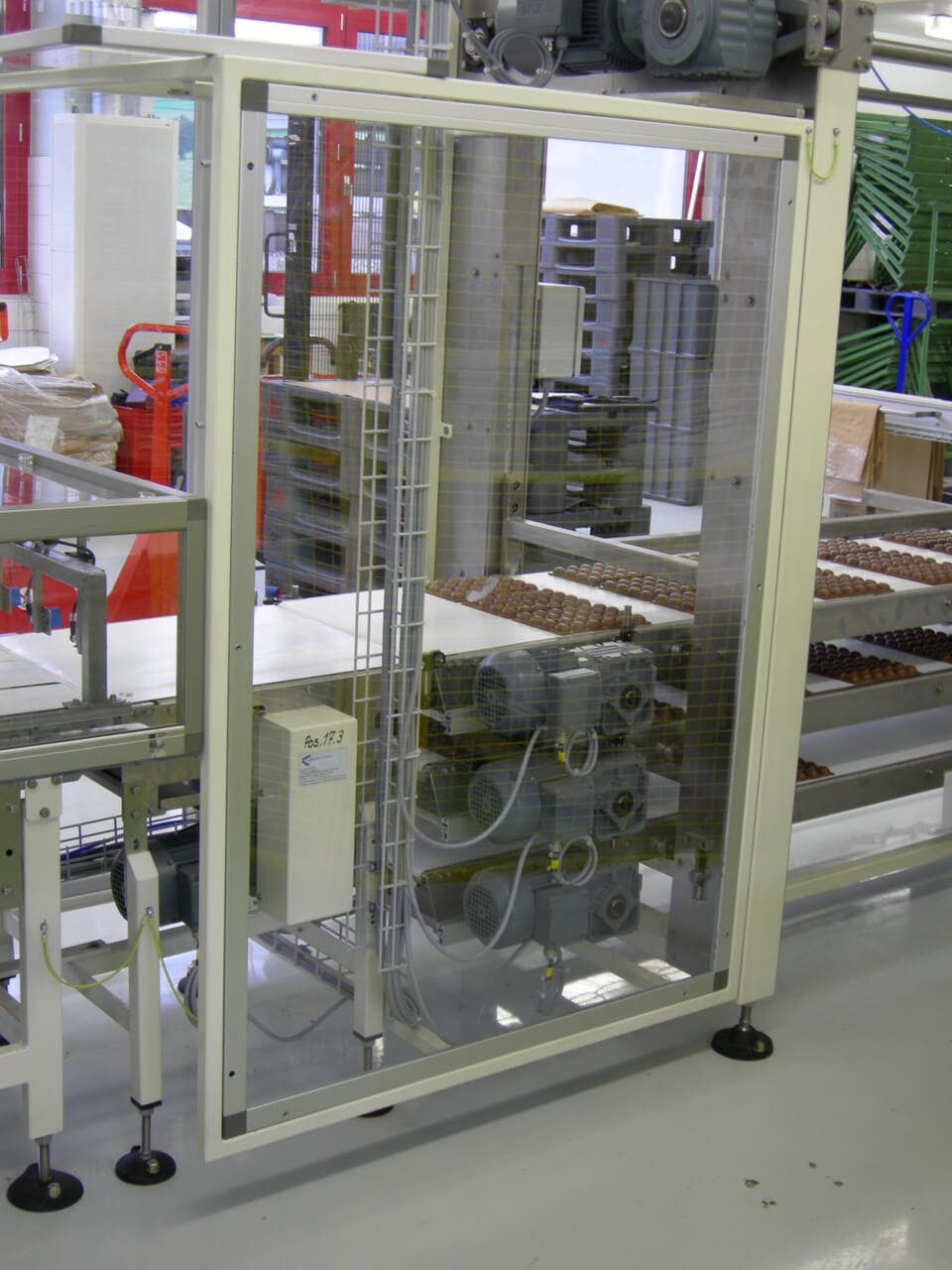

FIFO multilayer belt

FIFO accumulation system made with multi-level food mats, with step loading for space optimisation.

Technical features:

- Floor space: approx. 1.5 metres wide, 6-7 metres long for the slow version, 10-14 metres for the fast version

- Height: up to 2 metres

- Structure material: AISI 304

- Strip width: 800 to 1200 mm

- Accumulation: 12 to 32 metres

- Productivity: up to 60 rows per minute

The Buffer 5L is a system specifically designed to handle unpacked product in row lines, typical in chocolate, confectionery and bar production, and to be positioned upstream of the distribution line feeding the horizontal flowpack machines. The system comes in two versions.

For slow lines, composed of three overlapping belt conveyors mounted on a forklift that allows them to be moved in block. The intermediate belt is the normal transit belt and when the need arises to store product, the trolley moves to allow loading of the upper and lower belts. At the restart, each shelf is emptied at a higher speed than the nominal speed. The system works with FIFO logic, but in this configuration it does not allow complete product traceability.

The complete version, on the other hand, consists of a pre-sorting belt, a five-position tilting belt, five overlapping belts, one of which is the normal transit belt, and an unloading tilting belt, also with five positions. In this case the various shelves are filled and emptied in cascade, allowing, with the optimised software, FIFO with full product traceability.