Gates merger

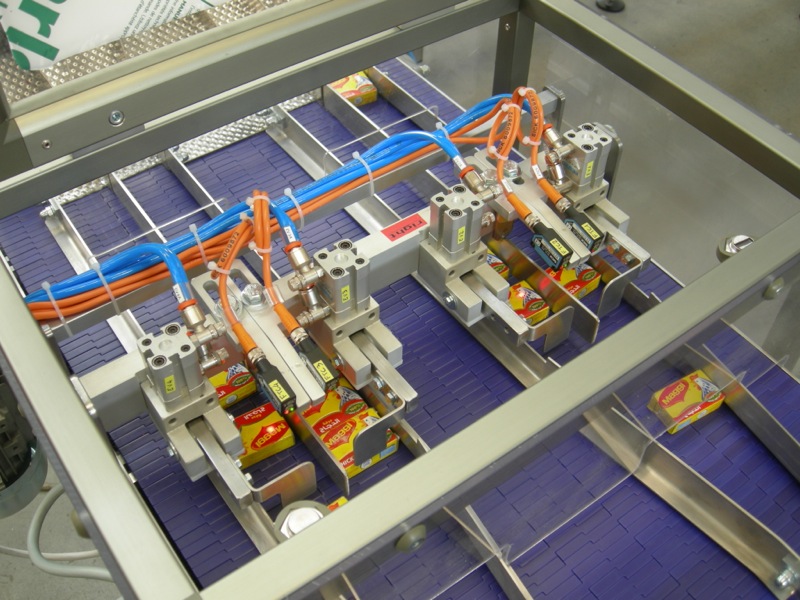

Pneumatically controlled mergingunits for products accepting accumulation with product train management.

Technical features:

Only for products that accept accumulation.

Great layout versatility.

Maximum productivity depending on available space.

Batch management.

Pneumatic or accumulation mergers are equipped with 'gates' on the infeed lanes that remain closed while waiting for the convergence section to be free, then releasing the rows of products in sequence. This simple and economical solution has two important prerequisites: the products must be able to withstand the pressure during the accumulation phase and the downstream machines must be able to receive the products in train without being stressed. The first point is intuitive because it concerns the integrity of the products and means that those permissible are boxes, trays, products stacked in tight packages.

However, it is more important to elaborate on the second point. At the exit of unification, the products are attached to each other or at least very close, but the belt speed is the same as it would be with regularly timed products and with a space between them equal to the size of the product itself. The average productivity of the line does not change, but when the train arrives downstream, the instantaneous productivity, from the machine's point of view, is double.

For this reason, either the machine can handle the situation, or it is necessary to normalise the flow with a deceleration belt and an acceleration belt after the unifier, which clearly requires more space, two additional motors and more complex control logic.