Heliflex

The Heliflex system is a high-capacity LIFO pressureless storage system also suitable for conditioning processes.

Technical features:

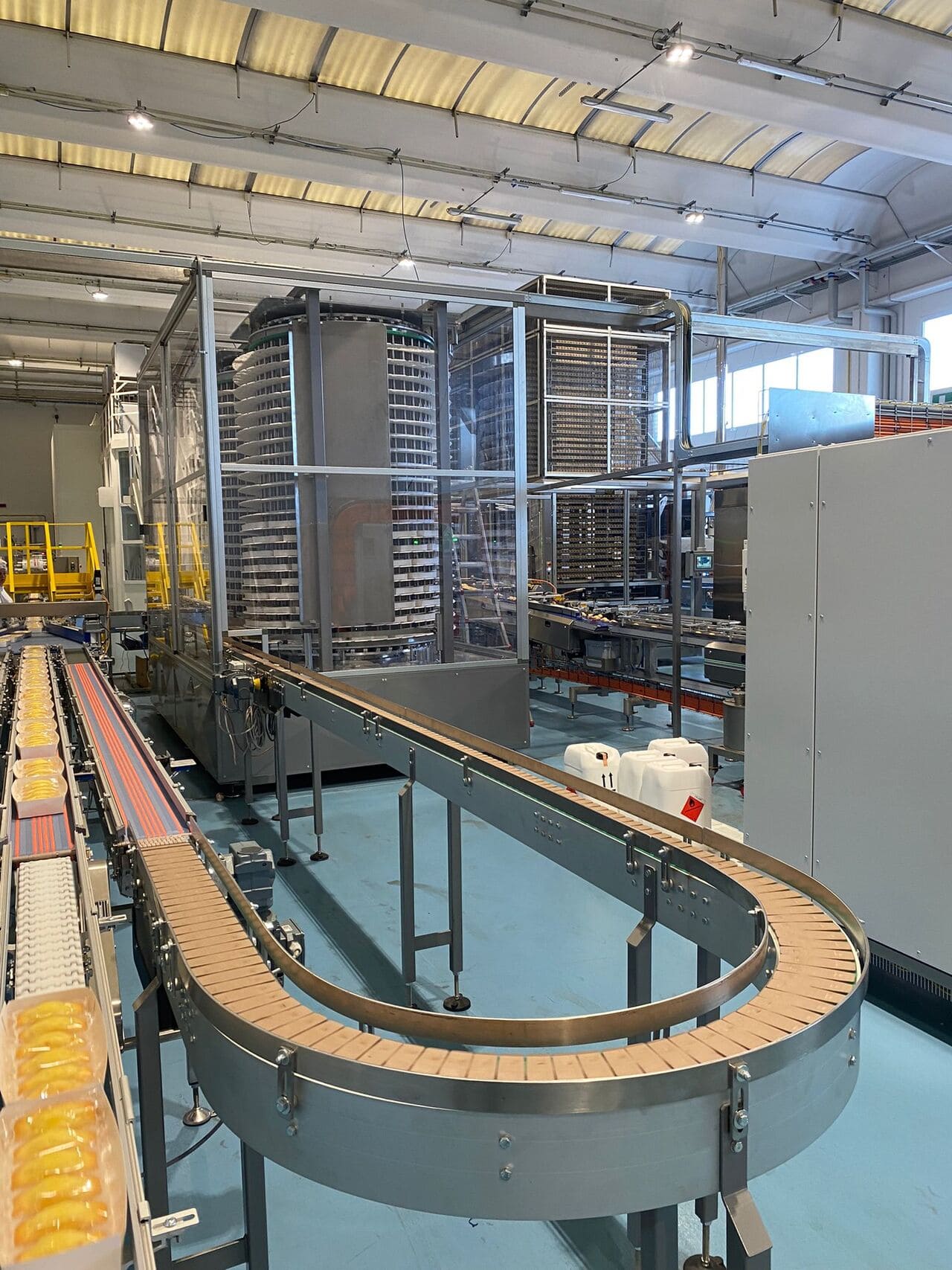

- Floor space: 3.5 metres wide, 5-6 metres long

- Height: from 3.6 metres

- Frame material: painted iron or AISI 304, with some aluminium components

- Belt width: 83 or 160 mm

- Accumulation: 130 to 400 metres

- Productivity: 120 - 180 ppm

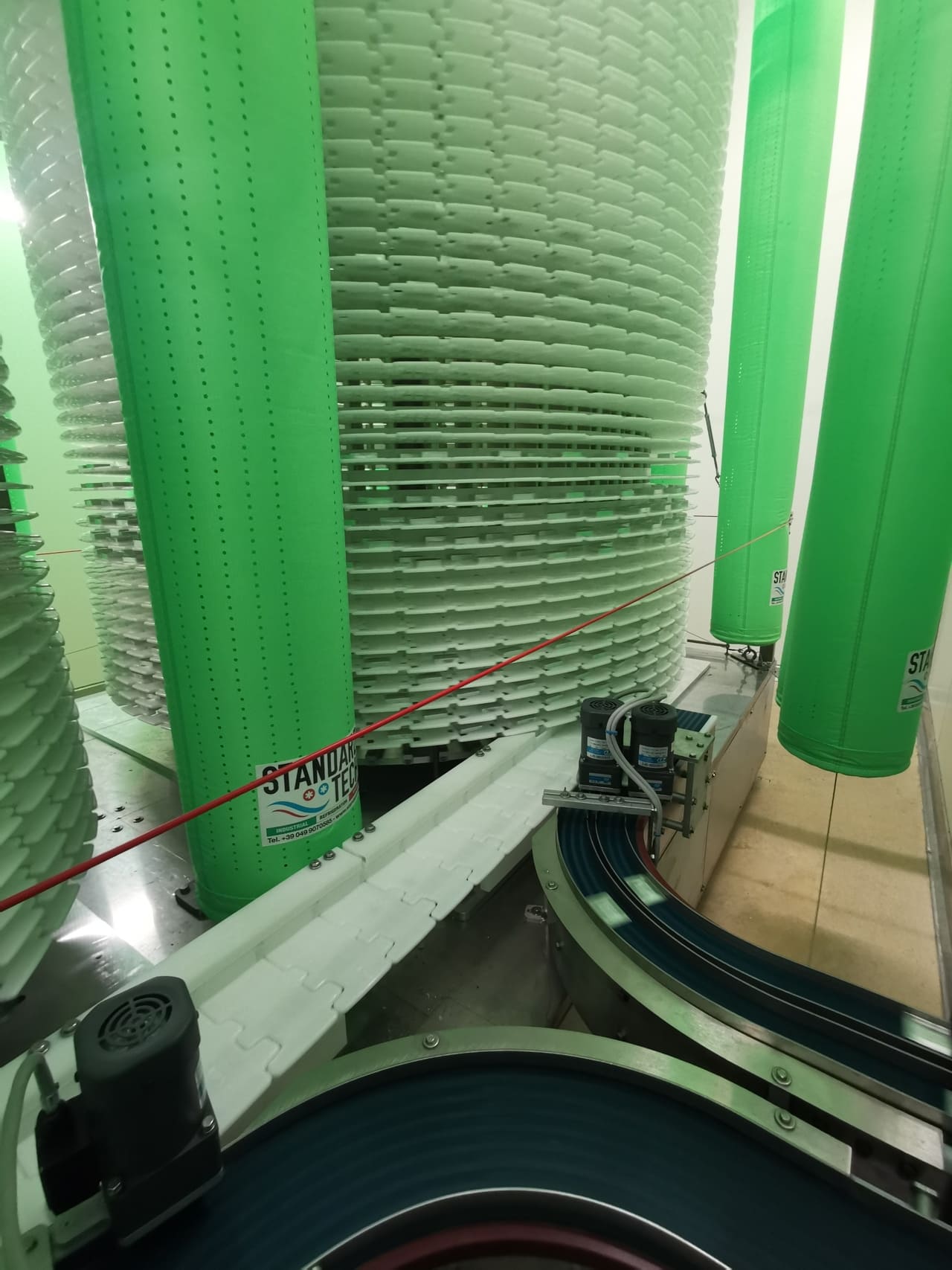

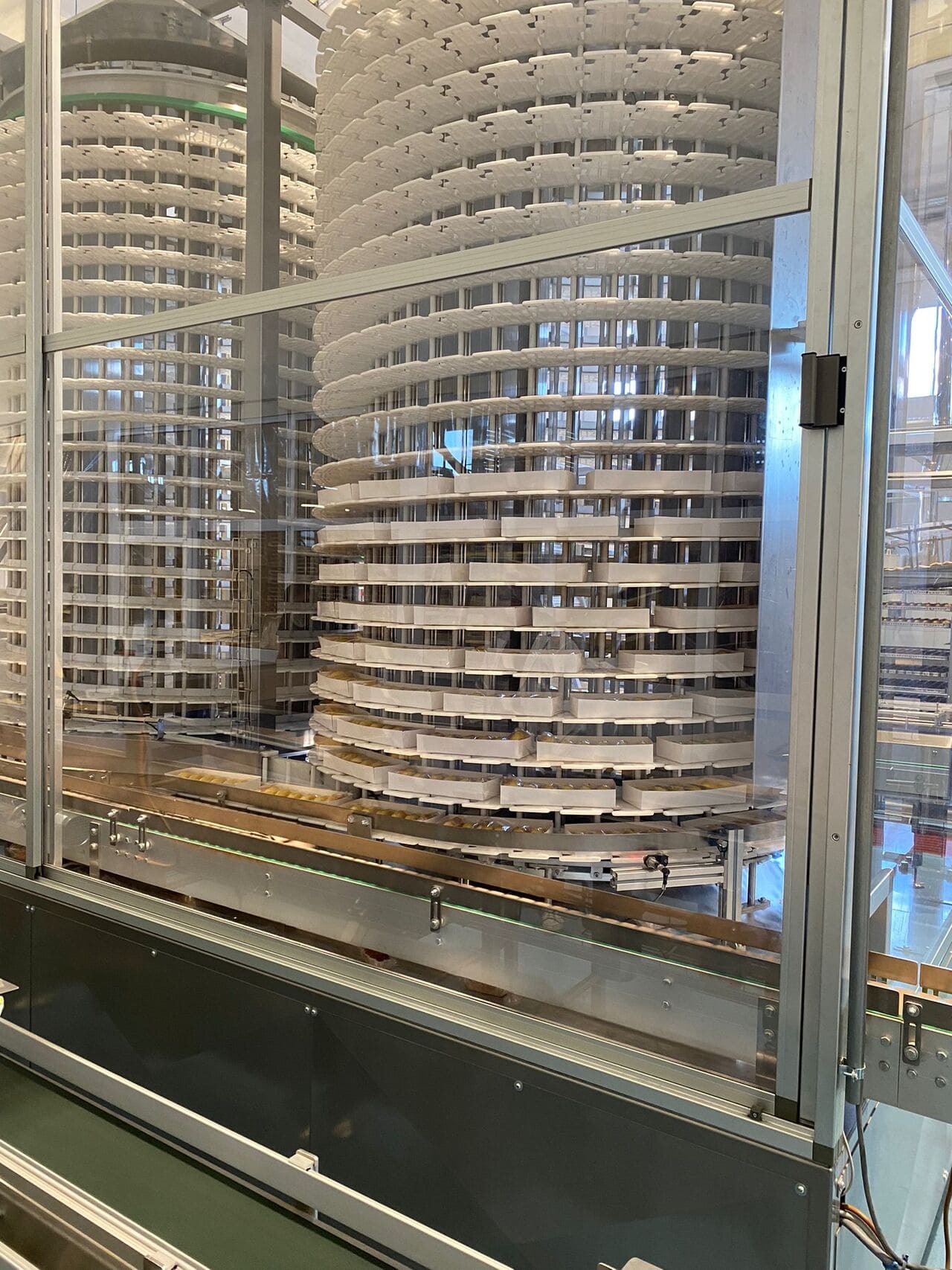

The Heliflex system exploits the potential of a unique chain to offer storage capacity that is unrivalled among devices of comparable size. The chain is helically wound onto a drum made up of a series of rods, which thus acts as a sprocket, and descends onto a second drum side by side to form a closed loop. The two drums are driven by mechanically synchronised motors. Each chain layer is supported by the one below. The maximum height of the products that can be handled depends on the spacer applied. Standard machines allow buffers with a maximum product height of 90 mm.

The mechanics of the system allow for all the best features of a flexible buffer system, including the possibility of continuous or discontinuous accumulation, the ability to return product to the line at any time without refilling the system, zero pressure that maintains perfect product and package integrity, and a large accumulation space ranging from 130 to 400 metres. The system operates with LIFO logic.

The products are fed in via a diverting system on the main line which, when the downstream machine stops, moves the incoming products onto a buffer conveyor. From this conveyor, the products are guided into the buffer system.

Thanks to the action of the inverter, it is possible to place the products on the buffer while maintaining a certain pitch so that they do not come into contact with each other and do not crush, preventing possible damage.

When the downstream machine becomes available again, Heliflex reverses its direction of travel and enters the unloading phase.

The unloading phase can also take place if upstream production stops, in this case at a higher rate.

The products can be reinserted into the line in 2 ways, the choice of which depends on whether or not the direction of travel is maintained with respect to the moment of insertion.

- In the case where the products must necessarily maintain the direction of travel in which they entered the buffer, there is a system for returning the products by means of a pneumatic pusher: the return at the downstream stop will be limited by the performance of the pneumatic system.

- In the case where the direction of travel of the products is indifferent for production purposes, the restitution can take place by means of a fixed deviation on an unloading belt and then by means of a unification system with the main line: the restitution at the downstream stop will be limited only by the unloading speed of the system.

The Heliflex system can also be used in cooling and conditioning systems, but it loses its characteristic of a buffer and becomes to all intents and purposes a long conveyor that is always traversed by products, whether at room temperature or in the cell.

TYPICAL PRODUCTS

Due to height limitations in the chain spacer, the Heliflex system finds its ideal application in flowpacks, low cartons and trays. When used as a packaging system, the most typical applications are in the dairy sector for processed or spreadable cheese.