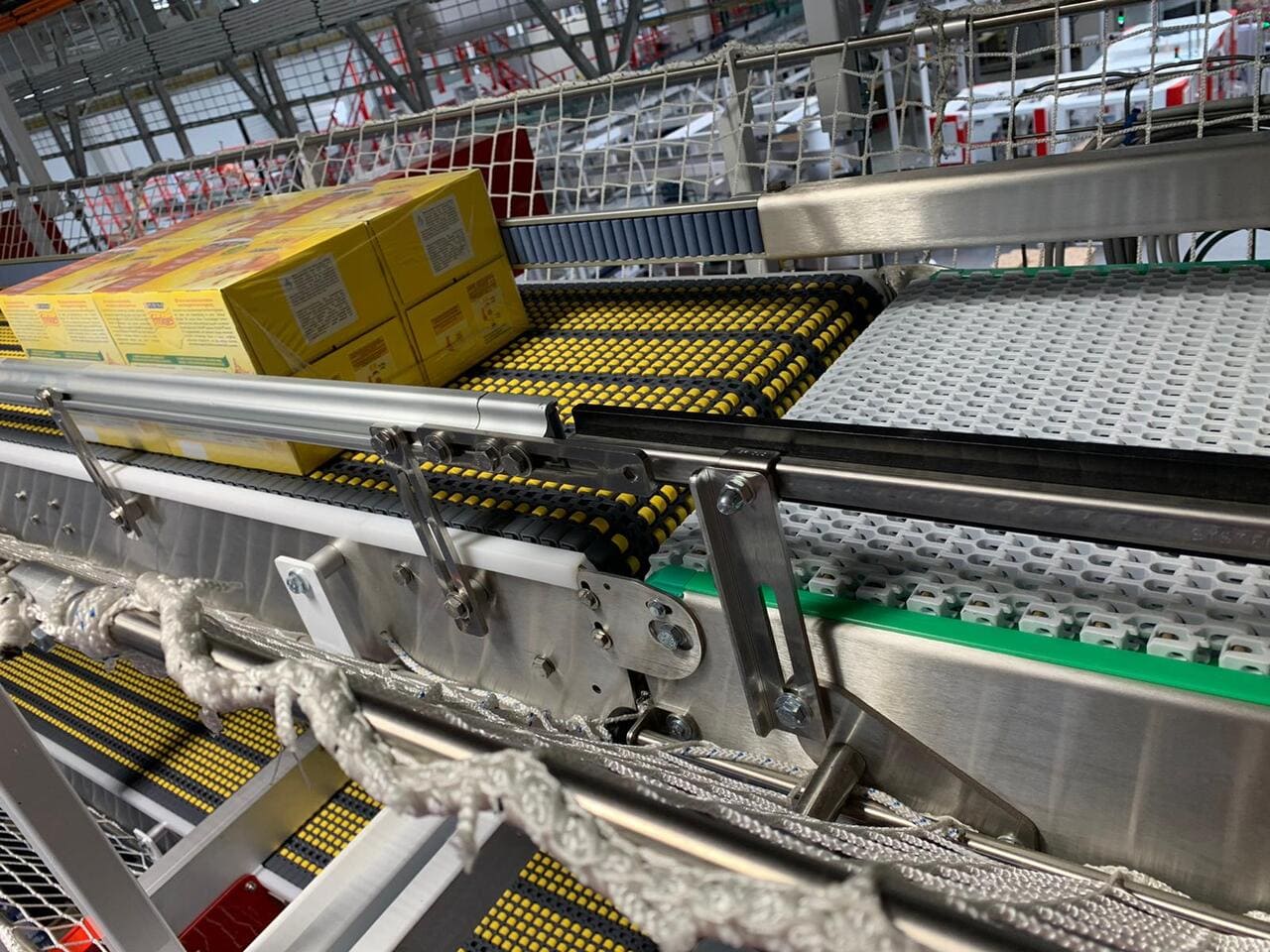

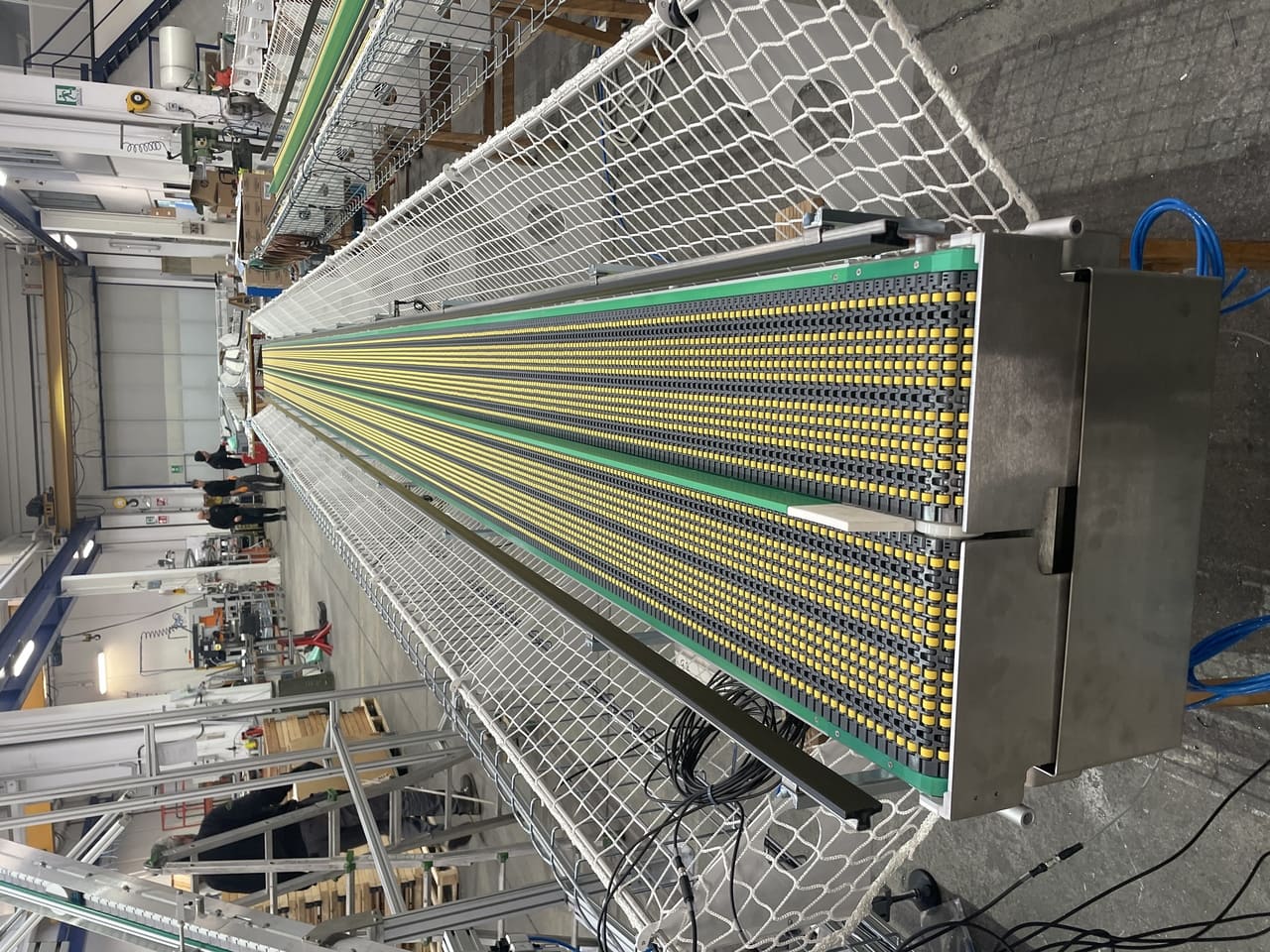

Low pressure conveyors

Conveyor belts with embedded rollers or friction rollers.

Technical features:

- Floor space: depending on conveyor width and length, overhead installation available

- Height: depending on the height of the plant

- Structure material: anodised aluminium AISI 304

- Strip width: approx. 300 to 600 mm

- Accumulation: depending on the space available in the factory

- Productivity: 20-30 packages per minute

If the products handled on the line allow accumulation with reciprocal pressure, the simplest and most economical way is to insert low-pressure conveyor belts. There are various technologies that allow this to be achieved, but in the food industry the one that has proven successful in recent years are modular chains with embedded idle rollers.

The accumulation space available is approximately half the length of the conveyors, since in this case the production always passes through the conveyors containing the device, so it is only possible to fill the spaces left empty. The natural application for low pressure belts is the accumulation of boxes, totes or bundles in the lines that feed the palletisers.

The recent trend is to install these belts in an overhead position to free up space in the plant. For multi-format lines, automatic clearance adjustment systems between the side guides, controllable from the operator panel, are available. Since any product, no matter how resistant, has pressure limits beyond which the package and its contents may be damaged, it is quite common to find pneumatic thrust-breaker stops distributed along the lines.