Dynamic mergers DU series

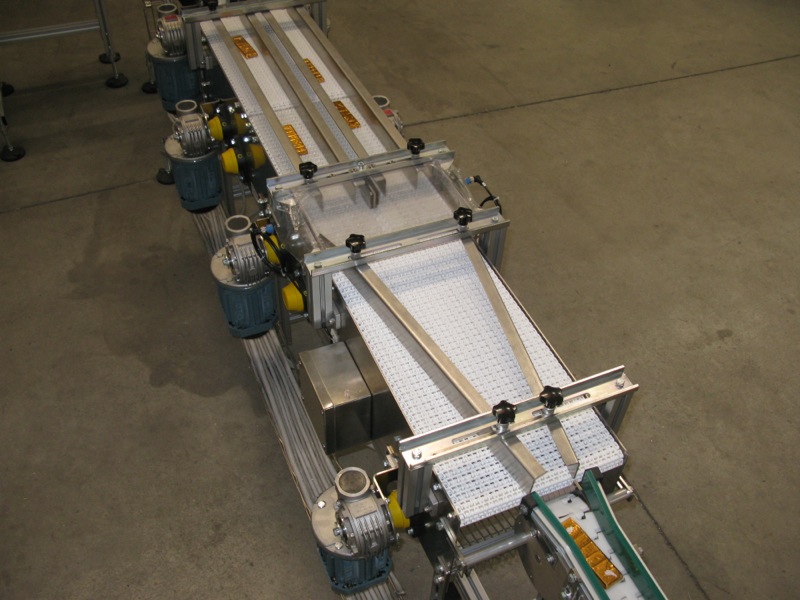

Dynamic Unifiers made with anti-coincidence belts at differential and controlled speeds.

Technical features:

- Non-contact system between products.

- Up to approx. 240 ppm.

- Available in carpet version with aluminium and AISI 304 construction.

- Washable AISI 304 version with modular chains.

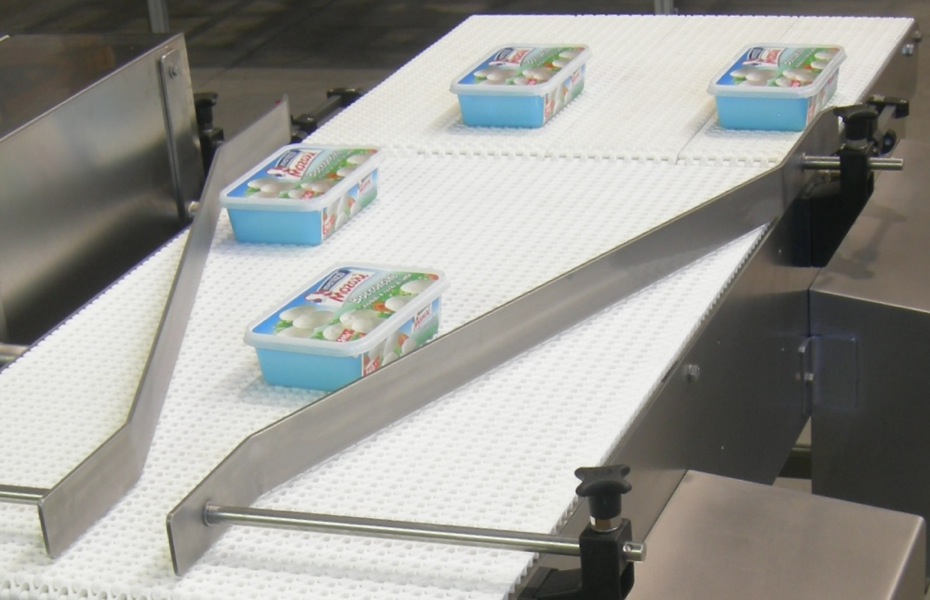

The DU series dynamic merging system represents the most versatile solution to the need for single lane merging of products in a packaging line. It works with anti-incidence phasing belts for each infeed track in a variable number depending on the required production rate.

Products are processed one by one, without contact, which allows any type of product to be processed, even those that do not allow reciprocal pressure, such as fragile products or those with a risk of overlapping.

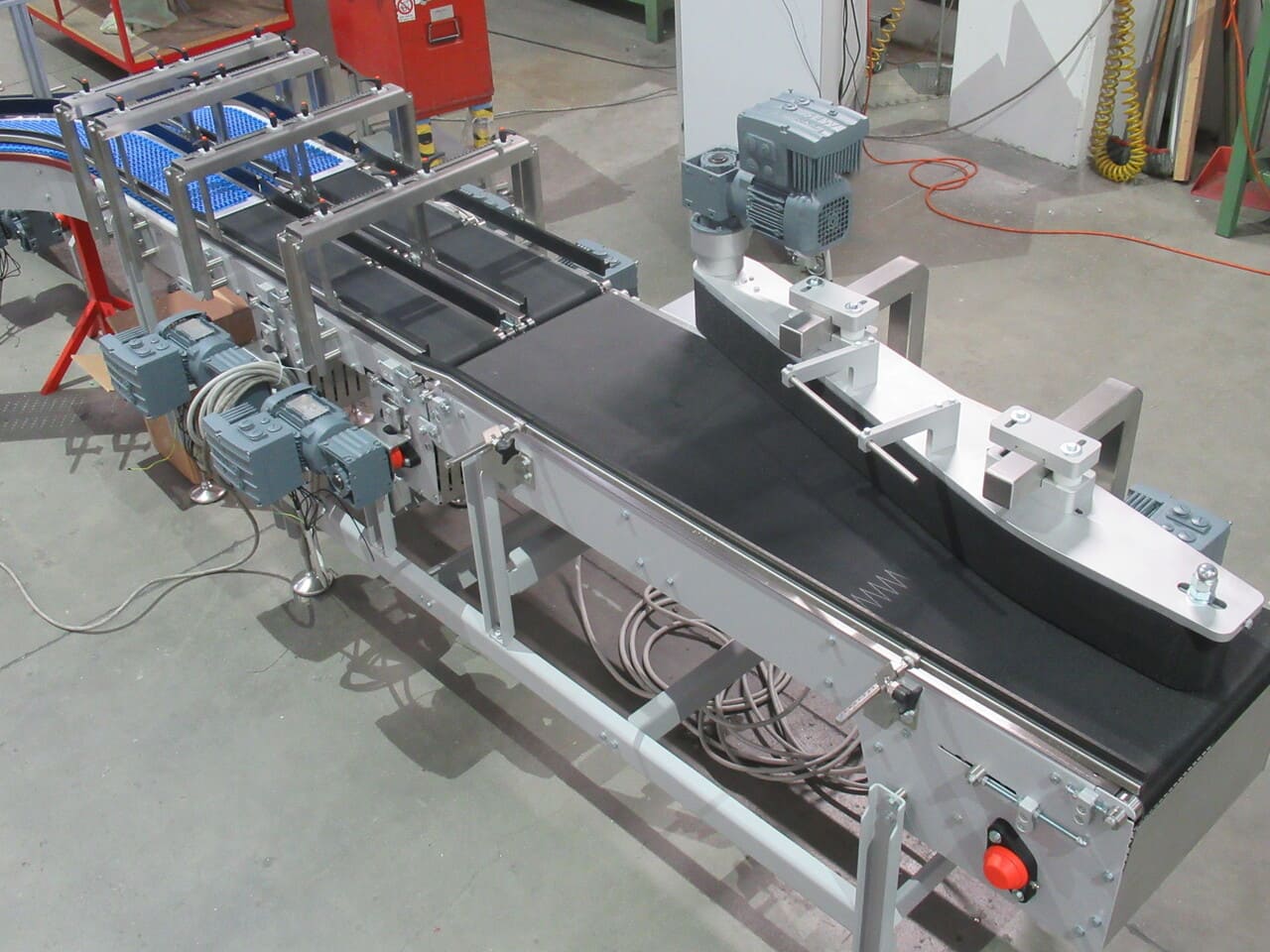

There are three versions of the DU unifier:

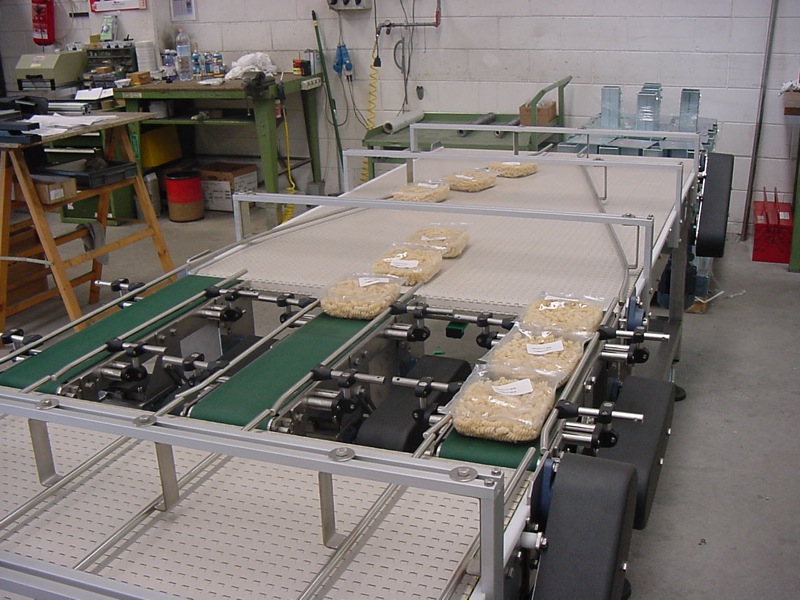

- DU45: A conveyor with an anodised aluminium structure, the most economical version and suitable for packaged products over 120 mm in length in dry environments.

- DU30: A conveyor with AISI 304 structure and 30 mm passage rollers, suitable for flowpacks over 70 mm in length, in dry environments.

- DUMX: A modular chain with AISI 304 structure, completely washable, suitable for the fresh food sector and typically placed at the exit from traysealers and thermoformers.