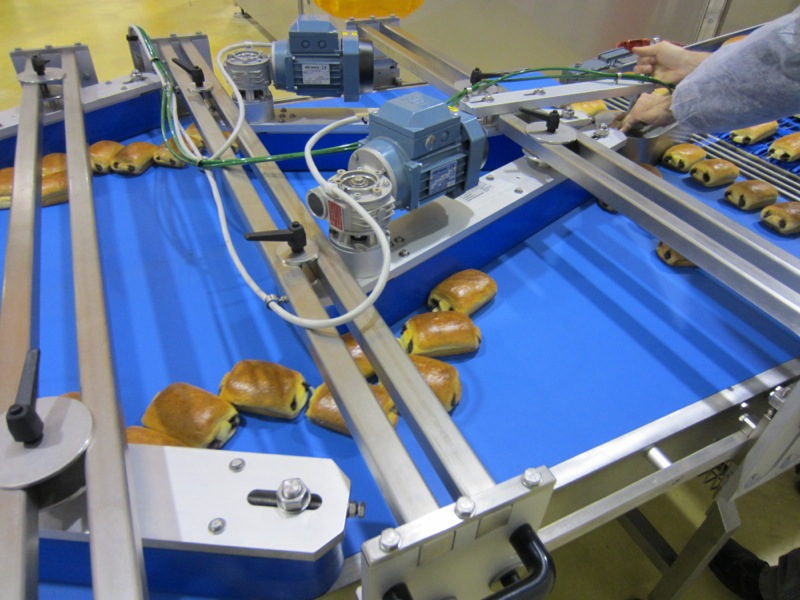

Chicaning systems

Chicane alignment system for products arriving in multiple rows.

Technical features:

- For bakery, chocolate or frozen food.

- At the outfeed from cooling lines.

- Products coming in on multiple rows for row reduction.

- Carpet or washdown version with modular chain.

- Available widths from 600 mm to 1600 mm.

In the bakery and confectionery sector, as well as in the frozen products sector, there is always a cooling or freezing system of some kind downstream of the process line. In modern high-throughput lines, all these systems are based on spiral conveyors; for this reason, at the exit, the products are often arranged in a disorderly manner or at least not perfectly aligned. Before feeding the machines performing the primary packaging it is important to arrange them in single file on one or more outlets, typically flowpacks. To meet this need, MH designs and manufactures unification and alignment units for unpacked products, both bakery and frozen products.

The system consists of a series of conveyor belts, typically wider than the chiller spiral, which perform speed jumps in order to distance the incoming products from each other. Above the conveyors there are, at the transition points between one belt and the next, fixed guides or motorised belt ploughs with adjustable inclination, which slow down some products while letting those that do not come into contact pass, thus carrying out the process of unravelling. The number of conveyors required to perform the alignment process depends mainly on the number of incoming rows and the shape of the products, although other factors such as the coefficient of friction of the products' surface may intervene. The construction of the conveyors can be either belt or modular chain, depending on the type of product to be processed.

The belt solution is ideal for the bakery and confectionery sectors, when there is the presence of filling or chocolate, and the products are very small in size, requiring head passes with small pens. Each belt is equipped with a pneumatic skid control and scrapers on the roller and counter-roller with a collection tray. The alignment guides in this version are almost always motorised ploughshares.

The modular chain, on the other hand, is more likely to be used with frozen products that do not present a risk of material adhesion to the belt surface, but require structures that are easily cleaned and generally resistant to moisture and corrosion. In most situations, frozen products are hard and slippery enough to allow the alignment guides to be made from a simple stainless steel plate.

Because of the path the guides force on the products these devices are typically called chicane aligners.