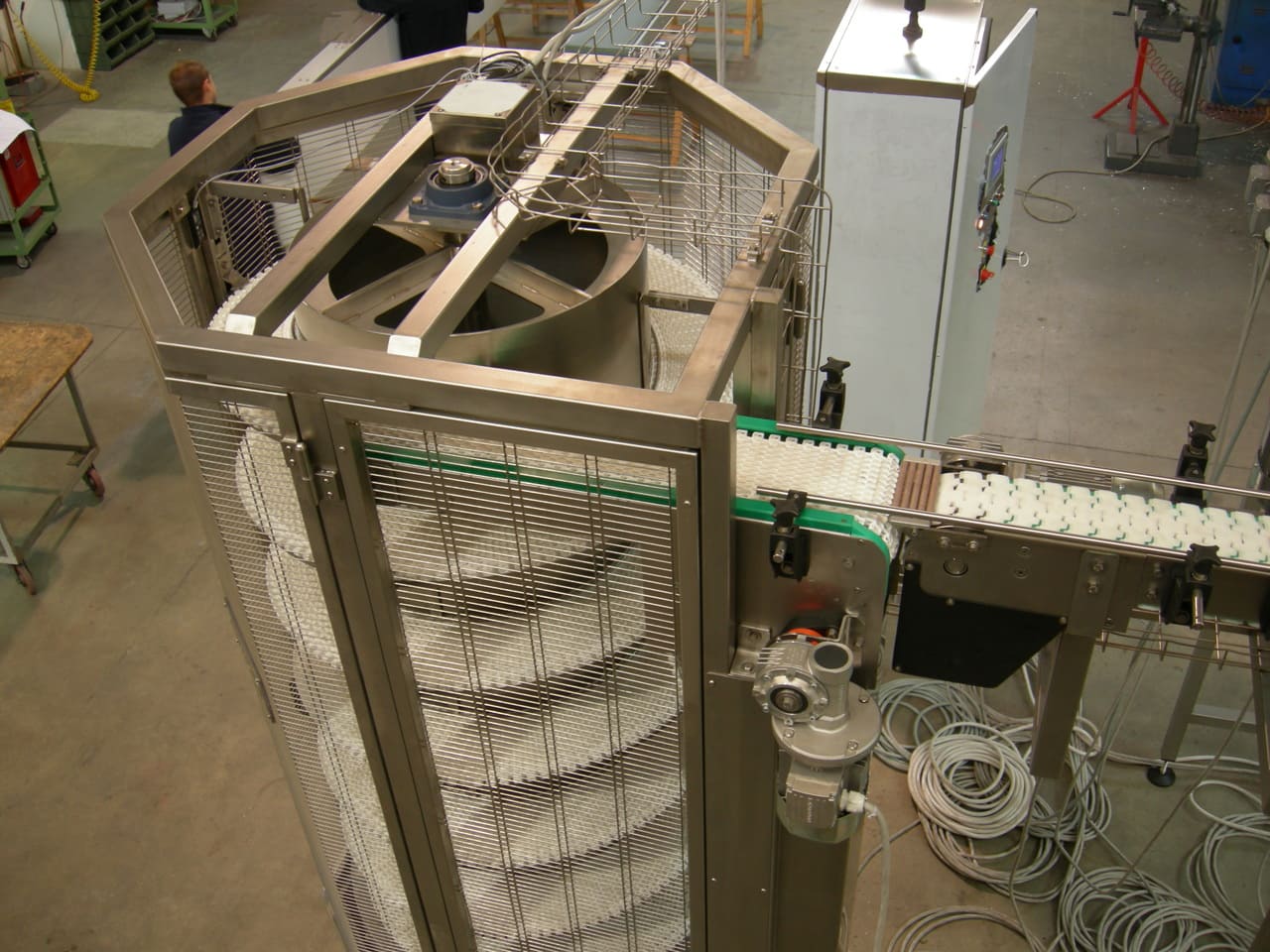

Spiral devices

Spiral conveyors with modular chain and rotating drum or tangential drive . Particularly suitable for solutions in the food industry.

Technical features:

Chain sizes ranging from 152 mm upwards.

Bending radius from 1.0 to 2.2 times the chain width.

Structures in AISI 304 or painted iron.

Fully washable Side Drive version.

Intralox offers three advanced spiral technologies: Overdrive, Side Drive and Direct Drive. These technologies are designed to meet the specific needs of various industries, ensuring optimum performance and reliability. Of these three systems, we can produce the Overdrive and Side Drive technologies under licence.

Overdrive

Intralox's Overdrive technology is designed to reduce friction by using a central rotating drum as the main drive element, and improve energy efficiency in spiral conveyor systems. Using a positive drive system, Overdrive enables smooth and continuous movement of products, minimising component wear and increasing system life. This technology offers the widest versatility in terms of attachments and chain bending radii, and is particularly suitable when keeping floor space requirements low compared to other solutions.

Side Drive

Intralox's Side Drive technology uses a side drive system that allows particularly complex configurations to be realised by distributing the number of drive points along the path. One of the most interesting aspects is being able to realise paths with the upward and downward coils nested within the same diameter. This system is particularly useful for applications requiring long paths such as cooling systems in the baking industry. Side Drive is, however, only suitable for actions at temperatures above 0°C.

Direct Drive

Intralox's Direct Drive technology eliminates the need for intermediate drive components, ensuring a direct transfer of power from the motor to the conveyor belt. The drive is via a central drum similar to the Overdrive, but in this it acts like a sprocket, engaging the chain directly. Direct Drive is ideal for applications in extreme temperature environments, such as cooling and freezing systems, where it is essential to maintain precise control of temperature and product movement.