The world of bakery products is rather vast and their industrial production reflects this with dedicated technological solutions; however, within them we can identify some macro-categories with replicable and consolidated production and packaging processes.

Let us begin by framing these categories, which already begin to differentiate by the type of cooling:

The first and most important is obviously bread, in all its forms.

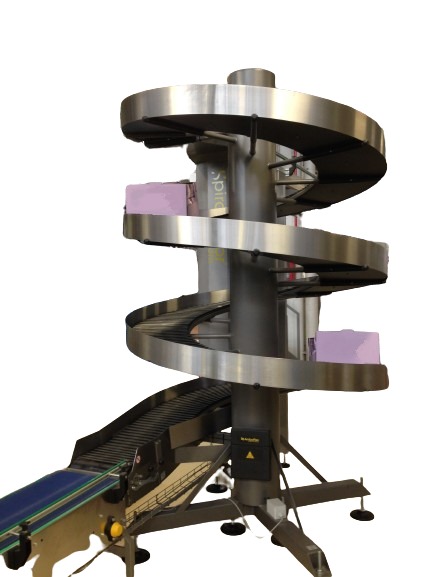

There are, of course, thousands of different types of bread and also a fair combination of ways of packaging it and bringing it to market. These various aspects influence both the transport and the design of the machinery; however, if we were to establish a general rule, the most common case involves cooling by means of a spiral conveyor. Crackers, Rusks and Dry Biscuits. All these products have in common that they are particularly fragile. Cooling takes place on wide belt conveyors, over many rows.

Shortbread Cookies.

Also in this case, cooling takes place on wide belt conveyors, but downstream the feeding system of the machines varies a lot depending on the type of package.

Confectionery products such as cakes and pastries.

Typical pastry or breakfast products. They are more 'malleable' than one imagines. They are cooled in spirals and packaged in horizontal flowpacks (again as for bread except for the mini products that go in verticals), and loaded with chicane alignment units.