The dairy sector is, among the various food productions, perhaps the one with the greatest variability in terms of production process, and this is particularly true in Italy.

Nearly 500 different varieties of cheeses are produced in the country, about 50 of which have EU recognition of protected origin.

If we add to these numbers all the other dairy products we realize the complexity of this market, which inevitably reflects on the technological part of the production process.

Industrializing a production process linked to gastronomic tradition while keeping the product's characteristics intact is a challenging and fascinating task, in which, however, MH intervenes only to a small extent and only in some niche products.

Tank outlet alignment

Contrast tilter

Denesters

Sani-Flex

Washable belts

In general, in addition to specific devices, Sani-Flex and Washable Belts take the lion's share.

Tank outlet alignment Contrast tilter Denesters Sani-Flex Washable belts

Horizontal flowpackers and VFFS

Wrappers

Doypack

Thermoforming machines

Thermosealing machines

Primary packaging in the dairy sector is also quite varied, we find horizontal flowpacks for solid cheeses, thermoformers or thermo-welded trays for solids and semi-solids, as well as for yoghurt, vertical flowpacks or doypacks for whey cheeses such as mozzarella or ready grated cheeses, and finally wallet wrapping for processed and spreadable cheeses.

Intralox spirals

Mergers

Bulk lines

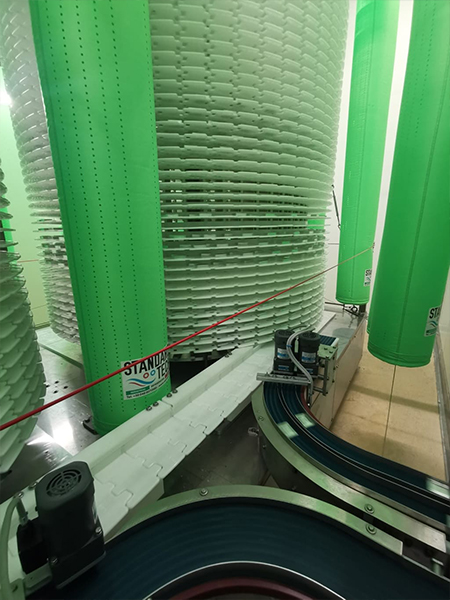

At the output of these machines, particularly for all those products that have a hot production process, cooling and conditioning systems are often found.

To meet this need, MH uses the Heliflex system, not as a LIFO buffer, but by adapting it to the application with a heat exchange system and an insulated enclosure.

For all types of packaging, before feeding secondary packaging, it is a good idea to use conveyor belts and devices that have fully washdown structures.

Special attention should be paid to materials. Sanitizations in this area use fairly aggressive chemicals to ensure that the bacterial load is lowered.

These can have a significant impact on the useful life of mechanical components. As for accessories, the most common are unitizing systems at the outlet of thermoforming or traysealing machines.

Intralox spirals

Mergers

Bulk lines

Clustering machines

Case packer

VFFS Multipack

Semi-automatic case packer

Secondary is often limited to shipping packaging, so tray or box, the exceptions being displays for snack-type products or clusters for small formats and yoghurt.

It is not uncommon, however, to find mozzarella in multipacks via vertical flowpack.

Sorter and ARB devices

Low pressure accumulation

Spiralveyor

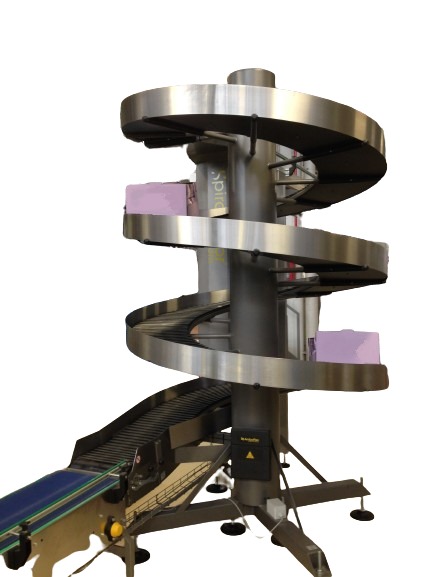

As previously mentioned, the use of manual palletizing is frequent. However, in cases of high production, the considerations for box lines adopted in other sectors remain applicable: roller belts or friction roller conveyors are used for accumulation, and activated roller belts for sorting and layer formation operations.

There is no shortage, of course, of the proverbial spirals to free up floor space and feed the palletizers from above.

Sorter

ARB devices

Low pressure accumulation

Spiralveyor

Cobot palletisers

Once we get to the corrugated box or tray level, a typical unit for pallet shipping, the solutions revert to those common to all markets: wide-chain, low-friction conveyors, friction roller conveyors, and Intralox ARB systems for package distribution and feeding to the palletizer.

For smaller and slower lines, we can add semi-automatic palletizers with Cobots to our portfolio.

Cobot palletisers