Pasta and rice are fundamental elements in the Mediterranean diet and are also widely consumed in many other global cuisines.

These are not high-margin products, which means that even more attention must be paid to the maximum efficiency of the lines and the best quality/price ratio.

Fortunately, the process is segregated from the packaging part and the product tends to be dry (for fresh pasta and shelves, such as ravioli and the like, please refer to the topic of ready meals as the lines are very similar), so there is no significant risk of bacterial build-up in the line.

Primary packaging is done with vertical filling machines in cartons or flowpacks or, in the case of rice, vacuum packing.

Table Top Conveyors

BAT Buffer

Product handling

The naked product can remain stationary in silos or belts for bulk products even for a long time, without forcing the primary packaging machines into a continuous cycle.

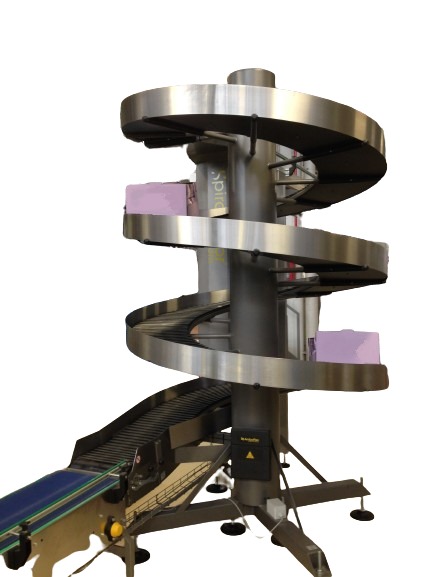

For this reason, accumulation or buffer zones between the primary and secondary do not require excessively long stretches and can be realised with linear accumulators or spiral systems of the Bat-Buffer type.

Product handling systems can be found to change the inlet configuration.

Table Top Conveyors BAT Buffer Product handling

Case packer

Stretch wrapping machine

Cartoning machine

Overwrapping, usually a cardboard box, is almost only present for rice and then the product is packed in an American box or wrapped around in wrap around or shrink wrappers.

Sorter and ARB devices

Low pressure accumulation

Spiralveyor

The next step leads directly to the palletiser and the transport solutions are those typical of box lines, with distribution systems using activated roller belts or pop-up roller conveyors.

The typical situation at this point is that of spiral conveyors that take the materials to belts installed overhead and direct them to palletisers that are often installed in different areas of the plant.

Sorter

ARB devices

Low pressure accumulation

Spiralveyor