The market for Ready Meals has been extremely interesting for many years now, a sign of social changes and changes in people's consumption habits, and in this sense we have seen various trends alternating:

- single portions for singles or those who eat quick meals at work

- frozen or freeze-dried family formats for families in which both members of the couple work full-time and have less time at their disposal

- or even vegetarian or vegan dishes

In this case, MH intervenes only at the end of the primary processing and packaging part, typically in trays or tubs, possibly limiting itself to managing the connection between cooking ovens and cooling or deep-freezing.

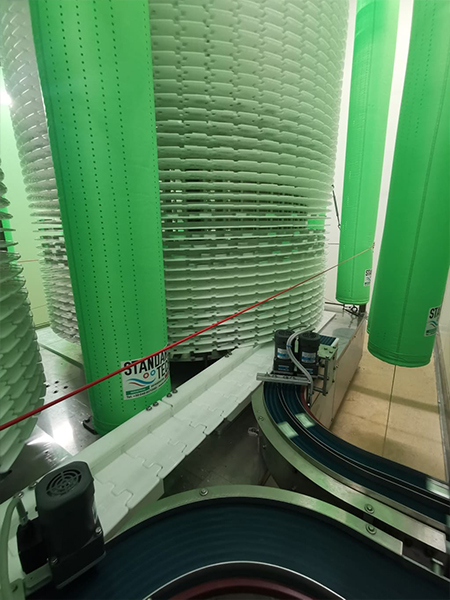

BAT Buffer

Heliflex

Mergers

Accuveyor

Also quite common are product distribution systems: tray mergers or dividers to handle the unloading of ovens and the loading of coolers.

In particular our Heliflex system can also be used in this sector as a cooling unit.

In every scenario, it is common to have strictly pressureless accumulation or buffer systems, typically located between the primary and secondary packaging. However, in certain situations, they can also be implemented between the process stage and packaging.

The choice between LIFO or FIFO systems depends on the maximum product dwell time outside the cold cycle.

MX Belts BAT Buffer Heliflex Sorters Mergers Accuveyor

Case packer

Thermosealing

With the exception of cases where trays enter the blast chiller or deep-freezer without a sealing film - a situation in which heat-sealing machines are also used - secondary packaging is generally carried out using trays, corrugated cardboard boxes or reusable plastic crates, which are ideal for distribution to the point of sale.

Sorter and ARB devices

Low pressure accumulation

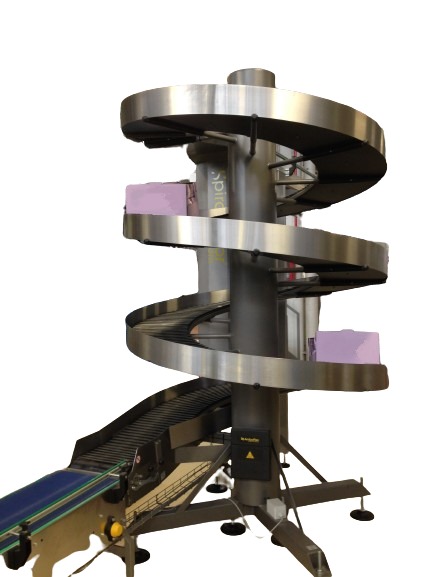

Spiralveyor

After secondary packaging, the usual box lines are connected to feed the palletisers, which, depending on the productivity of the line, can vary from fully automated to manual. In the latter scenario, we can offer palletising solutions using collaborative robots.

Sorter

ARB devices

Low pressure accumulation

Spiralveyor