The confectionery sector and in particular the production of snacks and snacks presents a great variety of products and therefore machines in the process stage, just think how different the production process of cereal bars can be, rather than coated sponge cake or any of the other variants we find on supermarket shelves or in the displays at snack stations.

Come vedremo, se il confezionamento primario è praticamente un monopolio delle flowpack orizzontali, è nel secondario dove si vedono più soluzioni differenti, quasi sempre trainate dal marketing e dai diversi canali di distribuzione che richiedono configurazioni differenti.

Row extraction lines

Row extraction lines

Flowpack

As mentioned, the horizontal flowpack is practically the only type of packaging in the snack world.

The only appreciable variations are whether or not the flowpack has an inner tray, corrugated cardboard base or can present more than one product per pack; however, these are packaging machine configurations that do not substantially change the line.

Buffer

Mergers

SVn-Bare lightweight spirals

Dividers

Snack and snack lines have reached very high speeds over the years, which is why it is unlikely to find accumulation systems between the primary and the secondary, while it is more likely to be found it placed between the multipack and the case packer.

In most cases, the flow of the wrapping machines is merged to feed a smaller number of wrapping or casing machines or divided for multi-row machines with a vision system.

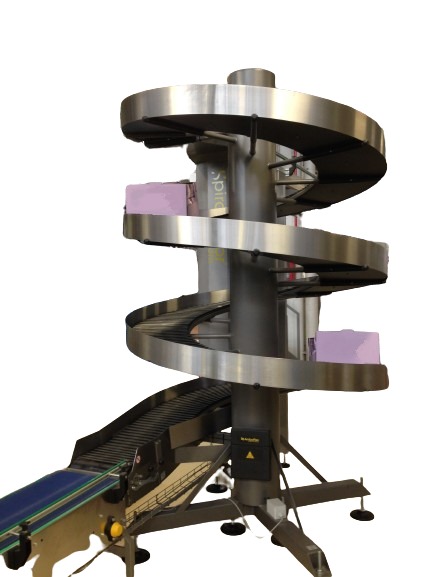

Another popular trend in recent years is to free up floor space by using lightweight spirals to connect with secondary machines overhead.

Buffer

Mergers

SVn-Bare lightweight spirals

Dividers

Cartoning machine

Tray packer

Overwrapping flowpack

Case packer

Secondary packaging is basically of two types:

- cardboard trays with a flowpack as over-wrapping

- or printed and coloured cardboard display cases

Up to a maximum of around 600 products per minute, machines with sorter infeed are used. Conversely, for higher speeds we switch to islands with picking robots guided by vision systems.

Sorter and ARB devices

Low pressure accumulation

Spiralveyor

Moving towards the end of the line, buffers can again be encountered, but given the level of investment, it is more likely that the machines used for the bare product will also compensate for the stops from the secondary line onwards.

Finally, the box conveyors and palletiser feeders see the usual technologies applied, from embedded roller belts or friction roller conveyors for accumulation sections to activated roller belts for sorting and layer formation.

There are, of course, the proverbial spirals to free up floor space and feed the palletisers from above.

Sorter

ARB devices

Low pressure accumulation

Spiralveyor