The pet food sector is growing rapidly and has an increasing variety of brands and products for different needs, but in terms of packaging the vast majority end up in cans, pouches or doypacks.

In both cases, these are products that are pasteurised in order to extend their shelf life. In these processes, MH only intervenes at the output of the primary packaging machines.

Table Top Conveyors

BAT Buffer

Can stackers

Mergers

Some special devices such as can stackers or multi-flavour combination systems can be found in this market.

Table Top Conveyors BAT Buffer Accumulation counters Can stackers Mergers Taste Combiners

Case packer

Stretch wrapping machine

Cartoning machine

In fact, it is quite common for the secondary packaging for supermarket shelves to be a single display containing several product flavours to choose from.

Some manufacturers prefer to have several production lines working simultaneously, hence the need for the combination system.

Sorter and ARB devices

Low pressure accumulation

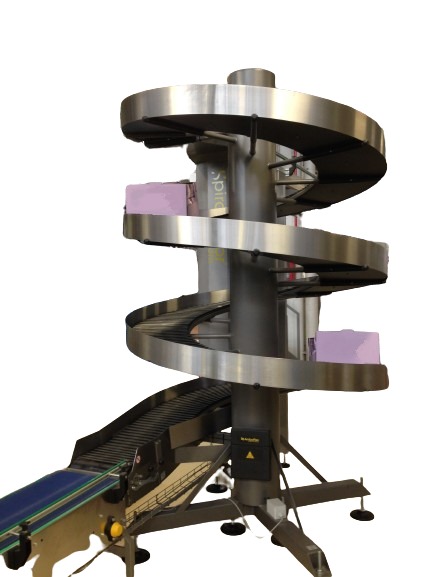

Spiralveyor

The boxes or bundles thus produced are then handled on the usual box conveyor lines to the palletiser.

Sorter

ARB devices

Low pressure accumulation

Spiralveyor