Coffee for sale to the public in supermarkets or specialised outlets comes in two forms: bags and vacuum packs on the one hand, capsules and pods on the other.

In both cases MH strictly intervenes after the primary packaging and the dedicated conveyors are of the table-top type.

Table top conveyors

BAT Buffer

Accumulation tables

Product handling

Both types of packaging often require a buffer between the primary and secondary packaging, and in the case of pouches or vacuum the ideal is a LIFO system such as our BAT-Buffer.

The same system can also be used for capsules, but if the geometry of the capsules allows it, it is definitely more convenient to go for a recirculation table.

Before secondary packaging, it is often necessary to handle the packages, especially for vacuum packs. Accessories such as blast chillers, straighteners and turning devices are the most common solutions integrated into conveyor lines to ensure optimal product preparation.

Table top conveyors BAT Buffer Accumulation tables Product handling

Case packer

Wrapper

Semi-automatic casepacker (capsules)

The secondary packaging is usually an overwrap in flexible film for vacuum packing, while in the case of capsules it is a cardboard box. Subsequently, it is transferred to a bundle or cardboard box.

Sorter and ARB devices

Low pressure accumulation

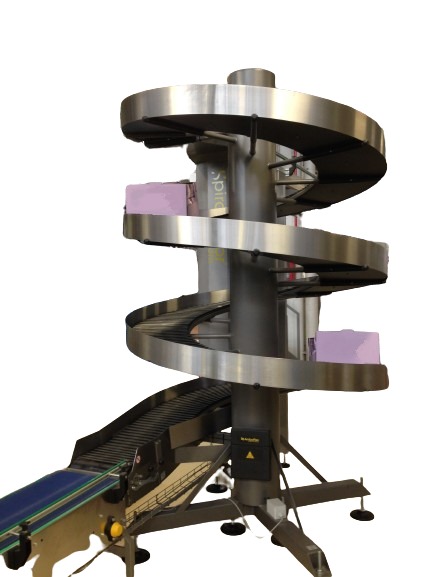

Spiralveyor

I nastri di trasporto scatole e alimentazione al pallettizzatore infine vedono applicate le consuete tecnologie, dai nastri a rullini o rulliere frizionate per i tratti di accumulo ai nastri a rulli attivati per sorting e formazione strato.

Non mancano, naturalmente, le proverbiali spirali per liberare lo spazio a terra e andare ad alimentare i pallettizzatori dall’alto.

Sorter

ARB devices

Low pressure accumulation

Spiralveyor

Cobot palletisers

The standard for this part is typical for box lines, thus including sorters, spirals and low-pressure accumulation belts. Sometimes it is possible to find bypasses that take the single pack directly to the last pack for shipment and these are always made with table top conveyors.

For small roasters with low throughputs we can add semi-automatic palletisers with Cobots to our portfolio.

Cobot palletisers