Talking about frozen food can be quite generic, in this case we exclude ready meals and ice cream to concentrate on the rest: pizzas, meat, vegetables and fried food.

MH intervenes at the exit of the cooling path in different ways depending on the type of packaging.

Bulk Lines

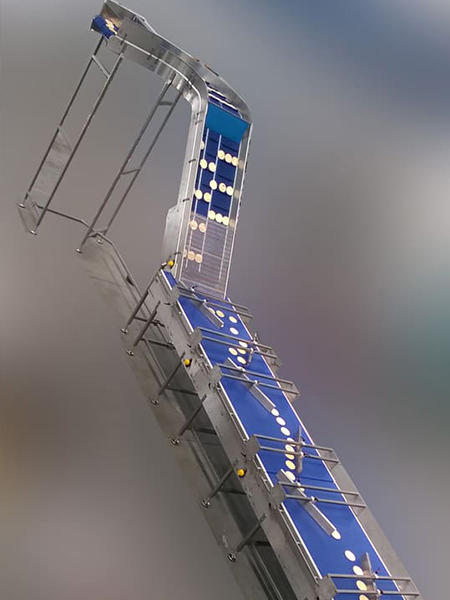

hicane aligners

Sani-flex

- products packaged haphazardly in bags by means of vertical flowpacks

- or products packaged individually or in groups sorted in horizontal flowpacks or cardboard boxes.

Horizontal machines, on the other hand, require aligning units through chicaning of one or more rows and possibly feeding systems to the machines that organize the products into regular groups.

n the frozen food sector, simple washable conveyors can still be found, but the trend in recent years is towards the hygienic design of the Sani-Flex system.

Bulk Lines Chicane aligners SaniFlex

Flowpack

Cartoners

VFFS

Traysealers

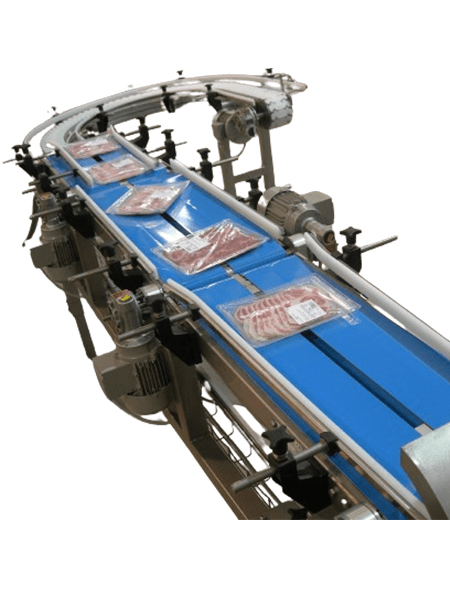

Flowpack machines, horizontal or vertical, represent a large part of the primary packaging of frozen products, depending on whether they are bulk or sorted.

In some applications it is still possible to find cartoners or traysealers.

Mergers

Accuveyor

Product Handling

Between the primary and secondary packaging there is a need for product handling and orientation systems, mergers and a general need for washable conveyor belts.

The need to maintain the cold cycle makes the use of accumulation systems rather rare; when they are needed, it is advisable to use FIFO buffers.

Accuveyor

Mergers

Product Handling

Case packer

SKU filler

Almost always one goes directly to the crate or box filler, if production is destined for the Horeca sector and reusable plastic crates are used.

Sorter and ARB devices

Low pressure accumulation

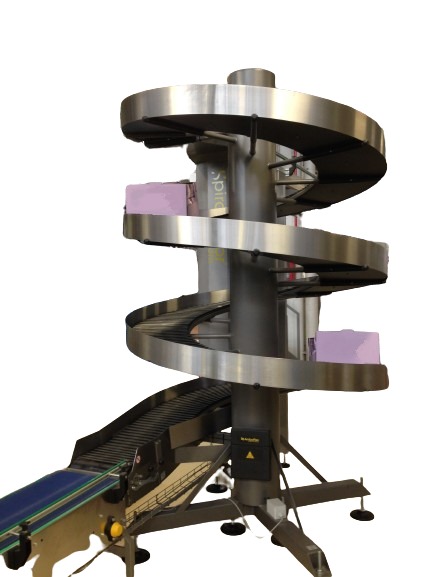

Spiralveyor

After secondary packaging and before the palletiser, all typical box line solutions can be implemented: spirals, sorters and low pressure accumulation. If this section of the line is in a humid environment, it may be necessary to opt for stainless steel structures to ensure durability and compliance with hygiene standards.

Sorter

ARB devices

Low pressure accumulation

Spiralveyor